Research area multi-material AM

The MultimaterialAdditiveManufacturing research area generates cross-faculty research ideas, identifies synergies and enables the use of research equipment for interested scientists at HTWK Leipzig and external parties.

The Multimaterial AM research area also links the cross-faculty Leipzig Centre of Materials Science with the Institute for Printing, Packaging and Processing (iP3) at the Faculty of Computer Science and Media, which has been researching the application of additive manufacturing processes in the context of traditional printing and packaging technology for many years.

- Targeted application of NC-controlled manufacturing for milling, turning and mill-turn workpieces for research, development and industry

- Use of additive manufacturing processes in medical technology, such as 3D printing of biomaterials for the development of innovative bone replacement materials

- Development of lightweight products using additive manufacturing methods

- Use of 3D measuring methods for reverse engineering processes

For example, we work on the processing of biodegradable plastics and biopolymers, the realisation of innovative solutions in casting technology and in the field of 3D scanning. We use the common CAD systems CATIA and Inventor to solve our tasks.

Tissue engineering is one of the working group's specialisms. The motivation here is to produce biological tissue artificially by means of directed cell cultivation, to replace tissue areas or to regenerate them completely. Complicated clinical pictures pose challenges if, for example, the recovery process extends over a very long period of time. Previously tried and tested strategies need to be reconsidered and further developed.

Implantable materials such as biopolymers (e.g. polycaprolactone; PCL) and hydrogels are biocompatible and can be degraded in the human organism over a longer period of time. Implants of this kind are mechanically stable immediately after application and do not have to be removed at the end of their service life by subsequent operations due to degradation in the body.

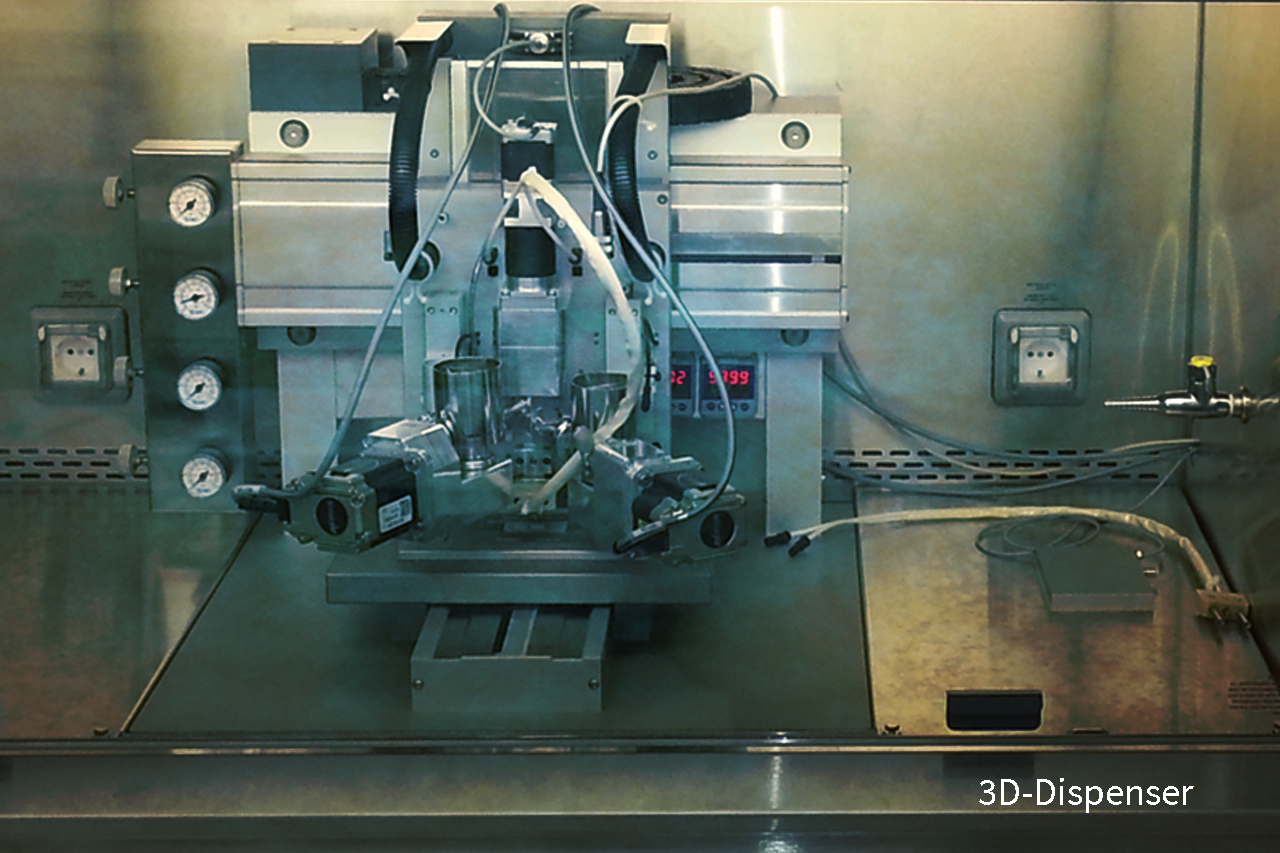

In order to transform promising biomaterials into geometrically defined complex structures, generative processes are used in the working group. We have made modifications to well-known 3D printers in order to come a little closer to the dream of 3D-printed implants. Along the way, we are sure to find a few more challenges that need to be solved.

- Section:

- FM

- Phone:

- +49 341 3076-2355

- Section:

- FING

- Phone:

- +49 341 3076-4119

- Section:

- FING

- Phone:

- +49 341 3076-4142

- Section:

- FING

- Phone:

- +49 341 3076-4239

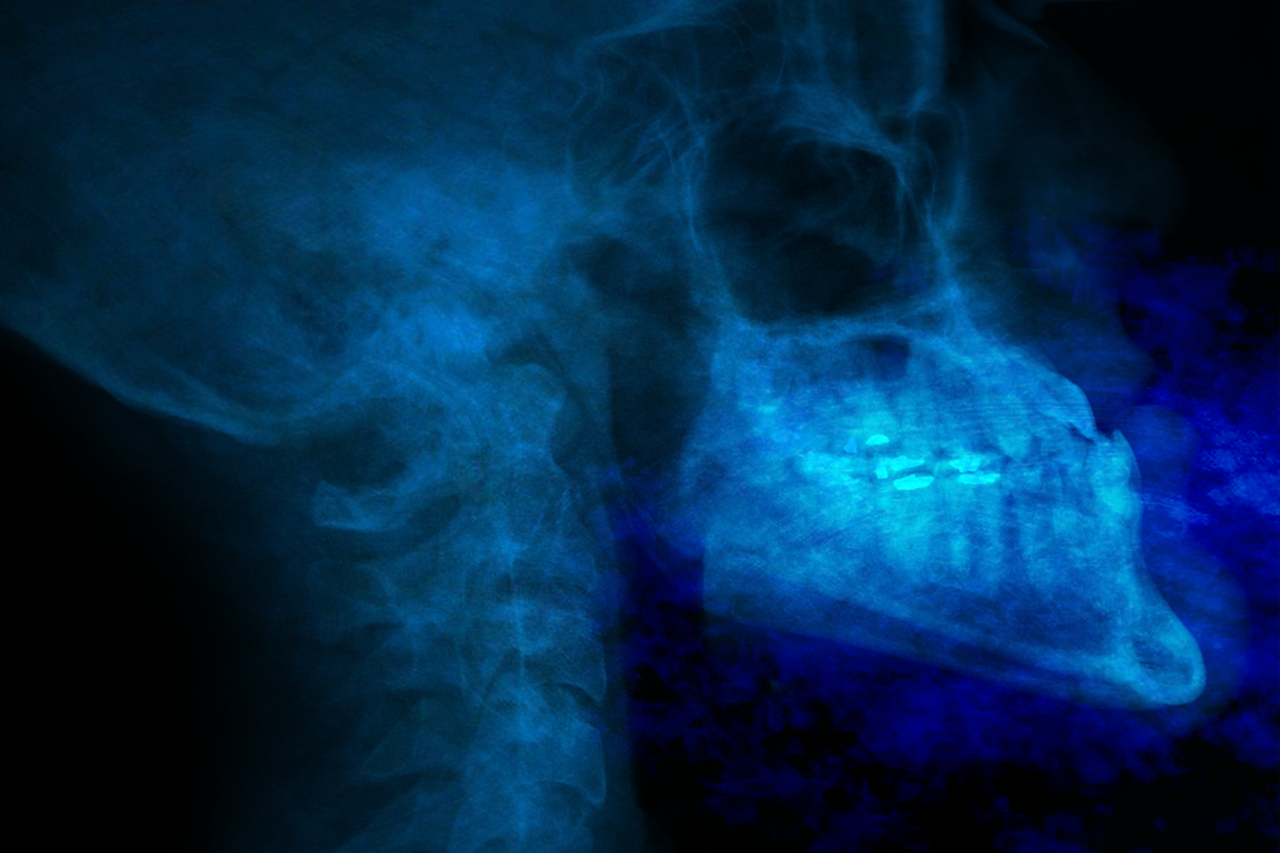

Development of a system for planning and osteosynthesis in orthognathic surgery based on anatomically preformed osteosynthesis plates and planning software

Within the project, a system for comprehensive planning, simulation and surgical treatment in orthognathic surgery is being developed. A central component of this is three-dimensionally preformed osteosynthesis plates for each area of application in orthognathic surgery of the human upper and lower jaw as well as the chin area, which enable simple and reliable intraoperative implementation of surgical planning.

Funding: ZIM of the BMWi (VDI project management organisation)

Project partners: Prof. Martin Gürtler (HTWK Leipzig), Anton HIPP GmbH

Project duration: 10/2020 - 06/2022

Development and validation of additive manufacturing strategies for the function- and geometry-preserving implementation of effective absorber structures in cable and housing components

The project is developing structures and manufacturing strategies that enable the additive manufacturing of components with an integrated sound attenuation function. This results in physically resilient components with reproducible and predictable damping properties.

Funding: ZIM of the BMWi (project management organisation AiF)

Project partner: Gesellschaft für Akustikforschung Dresden mbH

Project duration: 04/2020 - 10/2022

Investigation of the biocompatibility of generatively manufactured components

As part of the biocompatibility test, this project is investigating the cytotoxicity of various typical materials used in additive manufacturing from several processes.

Project partner: Fraunhofer Institute for Cell Therapy and Immunology e.V.

Project duration: 12/2020 - 12/2021

Novel embossing moulds with intrinsic, multidimensional property gradients

The aim is to develop new types of embossing moulds that can be produced for the first time using a combination of additive manufacturing processes and subtractive laser engraving. The additive structure offers completely new options for equipping the tool with geometrically highly variable, mould-optimised 3D embossing structures and specifically influencing the embossing properties of the tool.

Funding: ZIM of the BMWi (VDI project management organisation)

Project partner: SWG - Sächsische Walzengravur GmbH

Project duration: 06/2019 - 12/2021

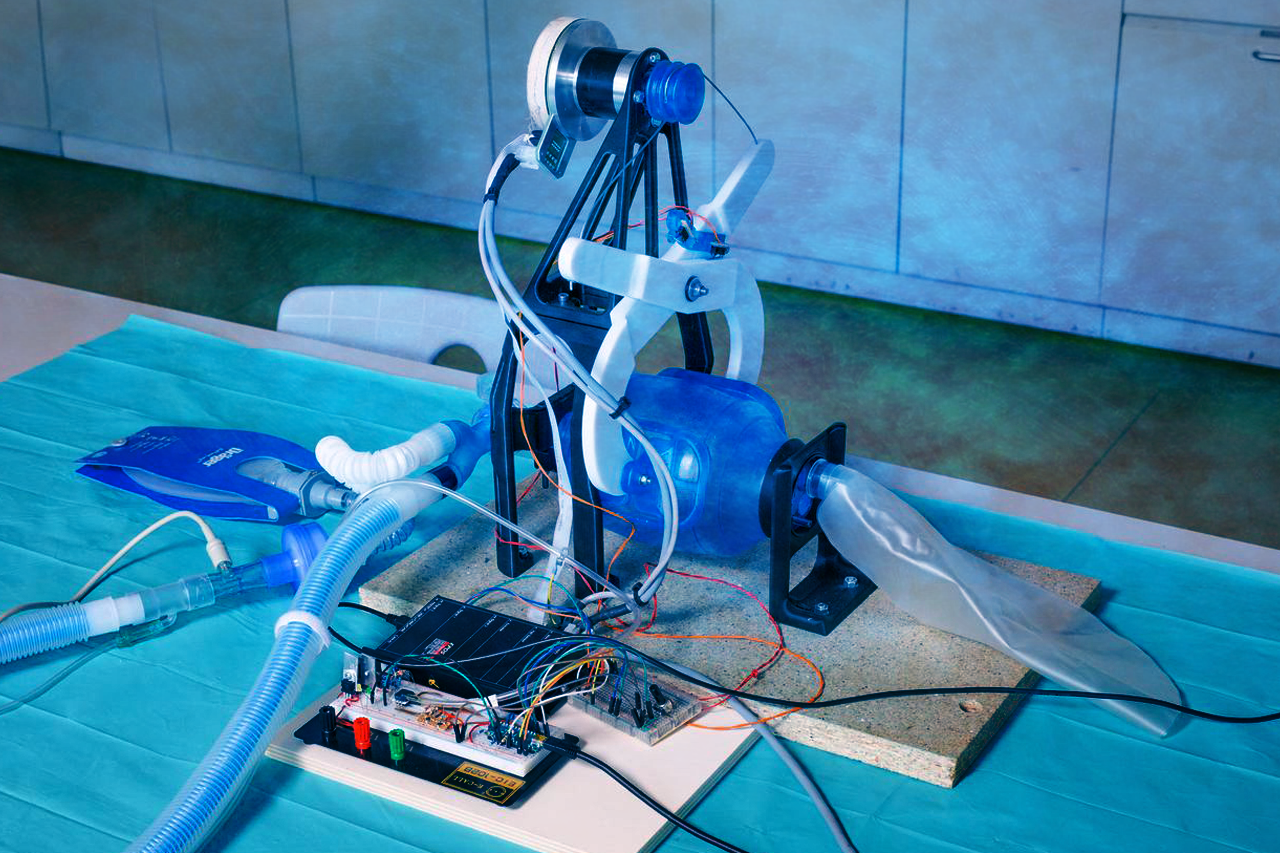

Development of an emergency ventilator to provide support during the Covid19 pandemic

An emergency ventilator was developed based on medical technology components available in the pandemic situation at the time, as well as freely available third-party components and additively manufacturable parts. The aim was to enable life-saving care for Covid19 intensive care patients in overcrowded intensive care units and the associated lack of professional equipment.

Project of an internally formed working group, without funding, cooperation with the company

Project duration: 04/2020 - 06/2020

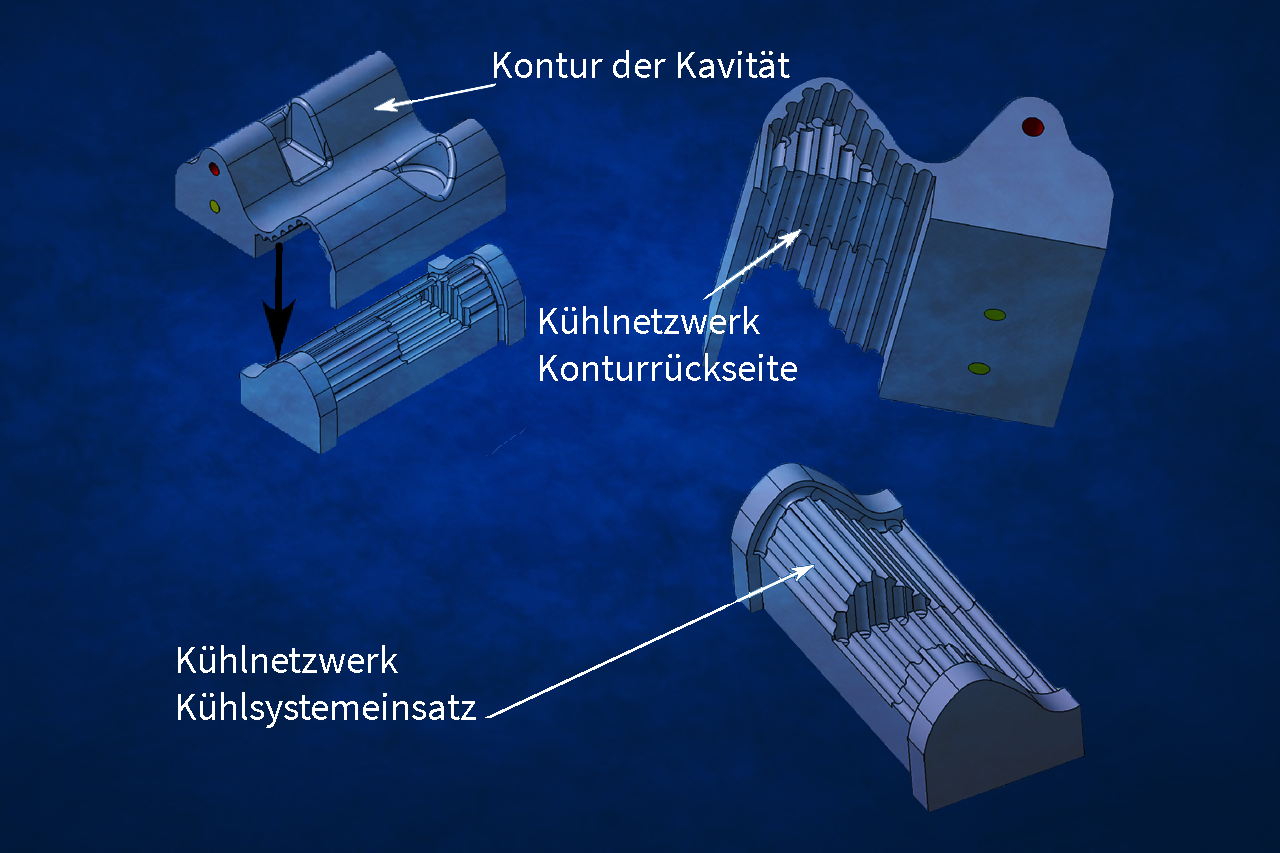

Process parameters and design step sequence of near-contour injection moulding cooling systems

New cooling systems for injection moulded plastic parts were developed as part of the project. By using 3D-printed inserts for the realisation of near-contour cooling, an extension of the degrees of freedom in terms of stability of the shot times and flexibility of the moulds was achieved.

Funding: ZIM of the BMWi (VDI project management organisation)

Project partner: TriWeFo - Tridelta Werkzeug- und Formenbau GmbH, Hermsdorf

Project duration: 05/2018 - 11/2020

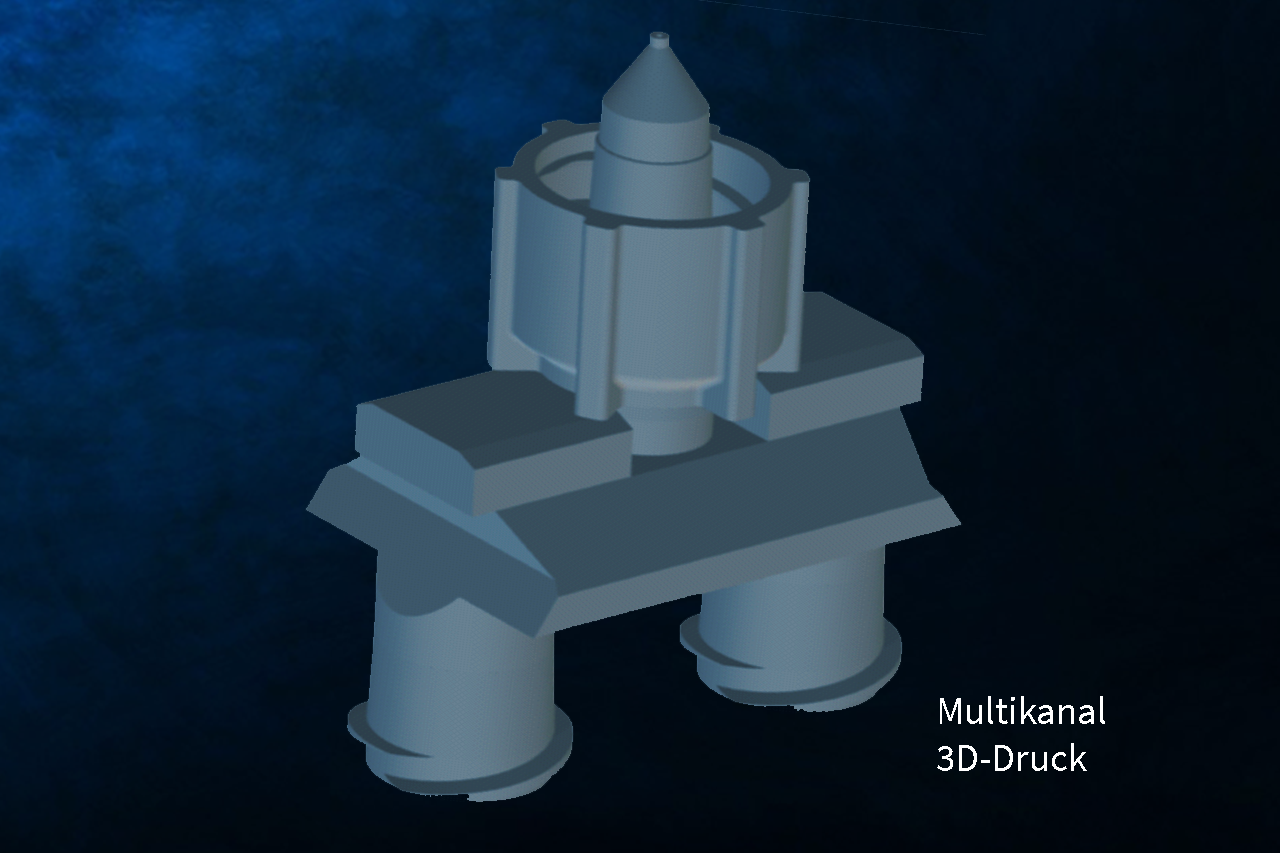

Generative production of multi-channel tubes for peripheral nerve regeneration

Until now, the healing of defects in the peripheral nervous system has had limited success due to the complex anatomical structure of nerves. The "Multichannel Tubes" project aims to use a new hydrogel material and generative process to break new ground in the production of an implant that will support the body's own regeneration of nerve defects in a targeted and better way.

Funding: ZIM of the BMWi (VDI project management organisation)

Project partners: Chair of Pharmaceutical Technology/Institute of Pharmacy/Faculty of Medicine/University of Leipzig, axiss GmbH

Project duration: 11/2016 - 03/2019

Publication: Extrusion-Printing of Multi-Channeled Two-Component Hydrogel Constructs from Gelatinous Peptides and Anhydride-Containing Oligomers

DOI: 10.3390/biomedicines9040370

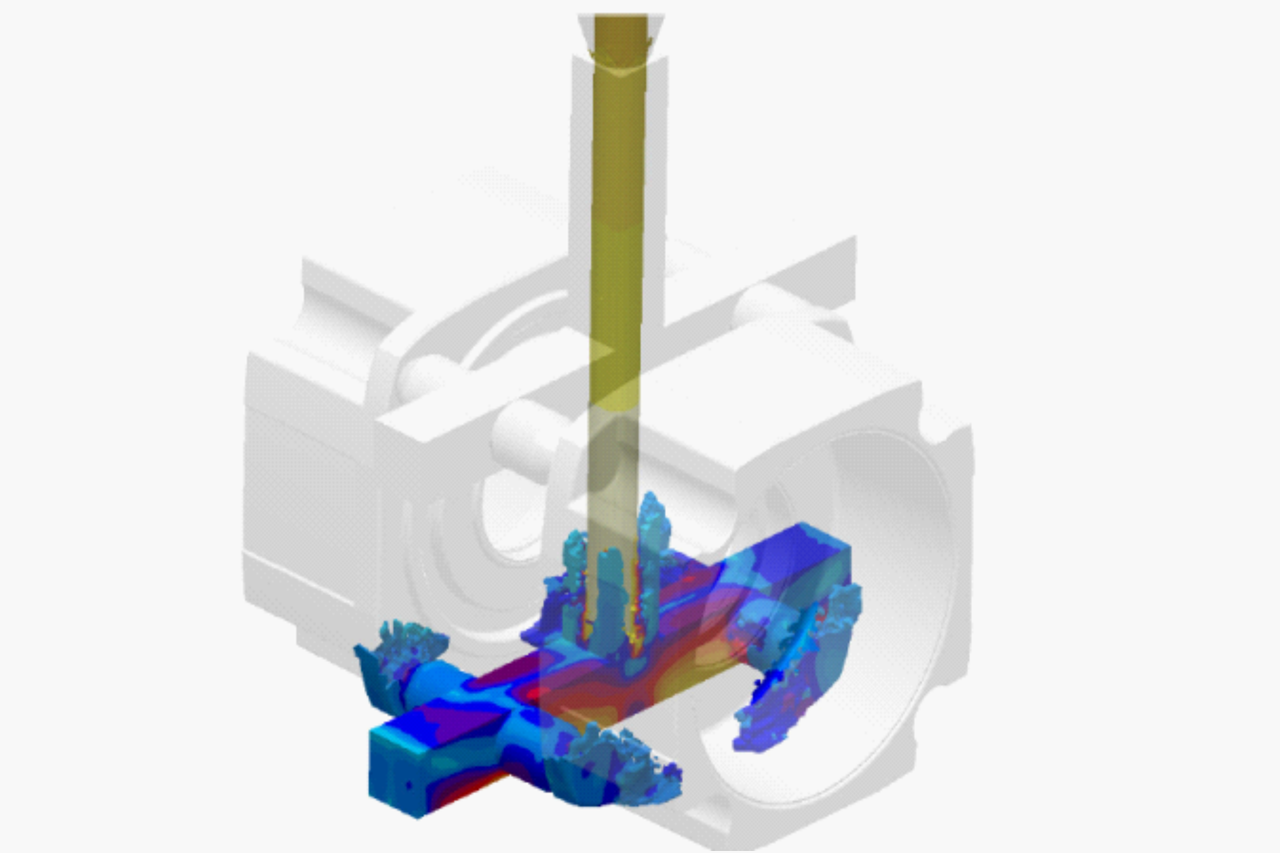

Simulations of cooling behaviour when using alternative moulding materials

Development of cooling systems for casting moulds to externally influence the solidification behaviour in metal casting, using vacuum-compatible moulding materials with poor thermal conductivity. The aim of the project was to control the cooling of metal investment casting parts by changing the moulding material and/or using cooling elements so that their quality approaches that of a component produced by die casting.

Funding: ZIM of the BMWi (VDI project management organisation)

Project partners: Prof. Henning Rambow/Faculty AS/HTWK Leipzig, Portec GmbH

Project duration: 06/2017 - 05/2018

Bone regeneration using 3D printed siRNA-releasing ceramic implants

Using a dosing head in the 3D printing process FDM (Fused Depsoition Modelling), bone cement pastes with an admixture of active ingredients are structured three-dimensionally. To this end, the system technology is being further developed to meet the requirements for processing pasty materials at room temperature with the process-integrated addition of powders. The aim is to further develop bone substitute materials.

Funding: SMWK

Project partners: Chair of Pharmaceutical Technology/Institute of Pharmacy/Faculty of Medicine/University of Leipzig, Clinical Pharmacology/Faculty of Medicine/University of Leipzig

Project duration: 09/2015 - 12/2017

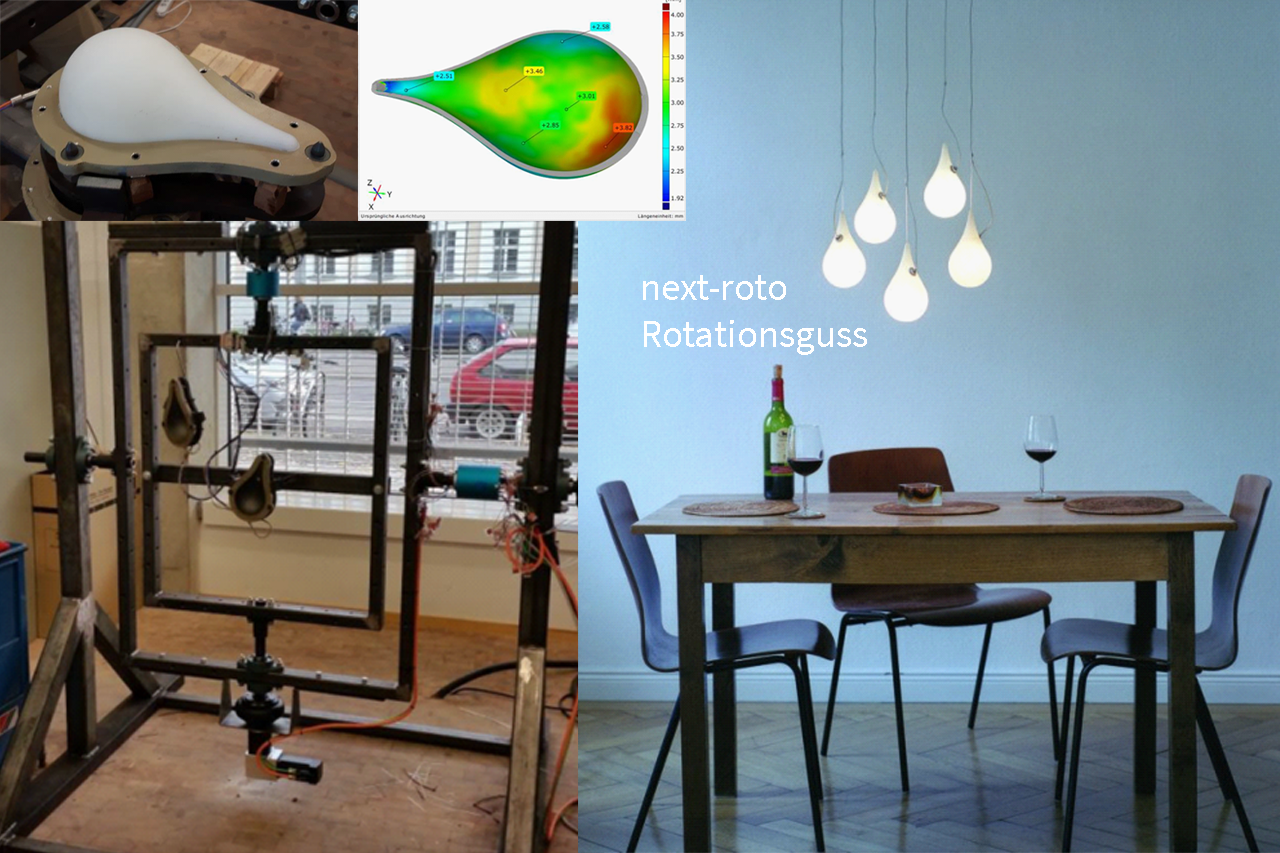

Development of new process engineering systems for innovative directly heated rotational moulds

The primary project objective is the development and prototypical implementation of new types of directly heated rotary moulds and an associated rotary machine for the production of complex plastic parts. The innovation goals are: new materials and manufacturing processes for the moulds, shortening of the production cycle, energy savings, energy recovery, reduction of space requirements, simplification of operation, significant improvement of product quality and reduction of rejects during rotation.

Funding: ZIM of the BMWi

Project partners: next home collection e.K. (practice partner), RWTH Aachen University

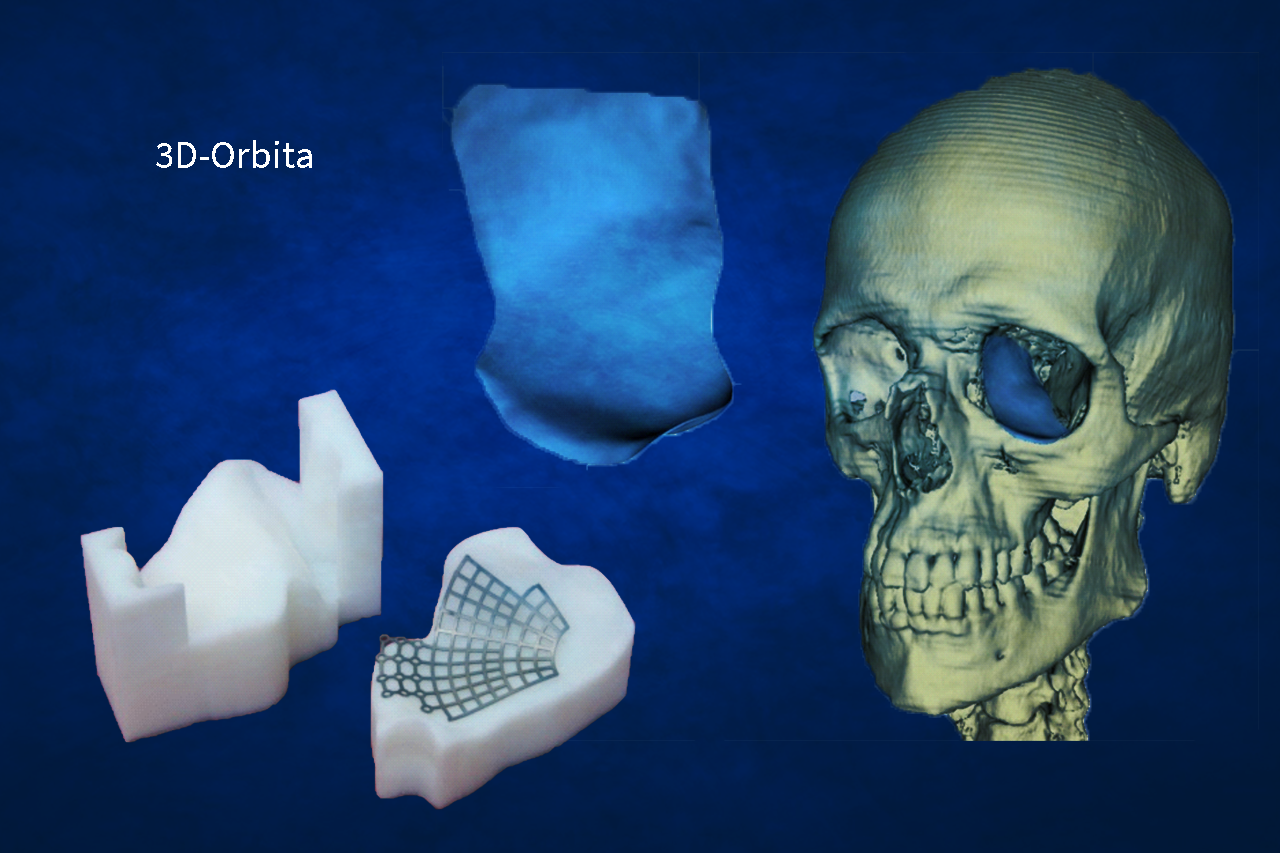

Development of a bending aid for the treatment of orbital wall fractures

The aim of the project was to create a process chain for the production of optimised patient-specific facial and cranial (craniomaxillofacial) implants.

Funding: ZIM of the BMWi (AiF)

Project partners: Deufel GmbH (practice partner), Clinic for Oral and Maxillofacial Surgery/Medical Faculty/University of Leipzig

Publication:Template-Based Orbital Wall Fracture Treatment Using Statistical Shape Analysis

DOI: 10.1016/j.joms.2017.03.048

Application of 3D prototyping processes for the microdosing of pharmaceutically active substances with homogeneous embedding in a bioplastic matrix

The research funding project created the prerequisites for submitting applications for new projects in the field of medical technology. The focus was on the generative processing of biocompatible plastics using the rapid prototyping process FDM (fused deposition modelling).

Funding: SMWK

Project duration: 08/2013 - 12/2013

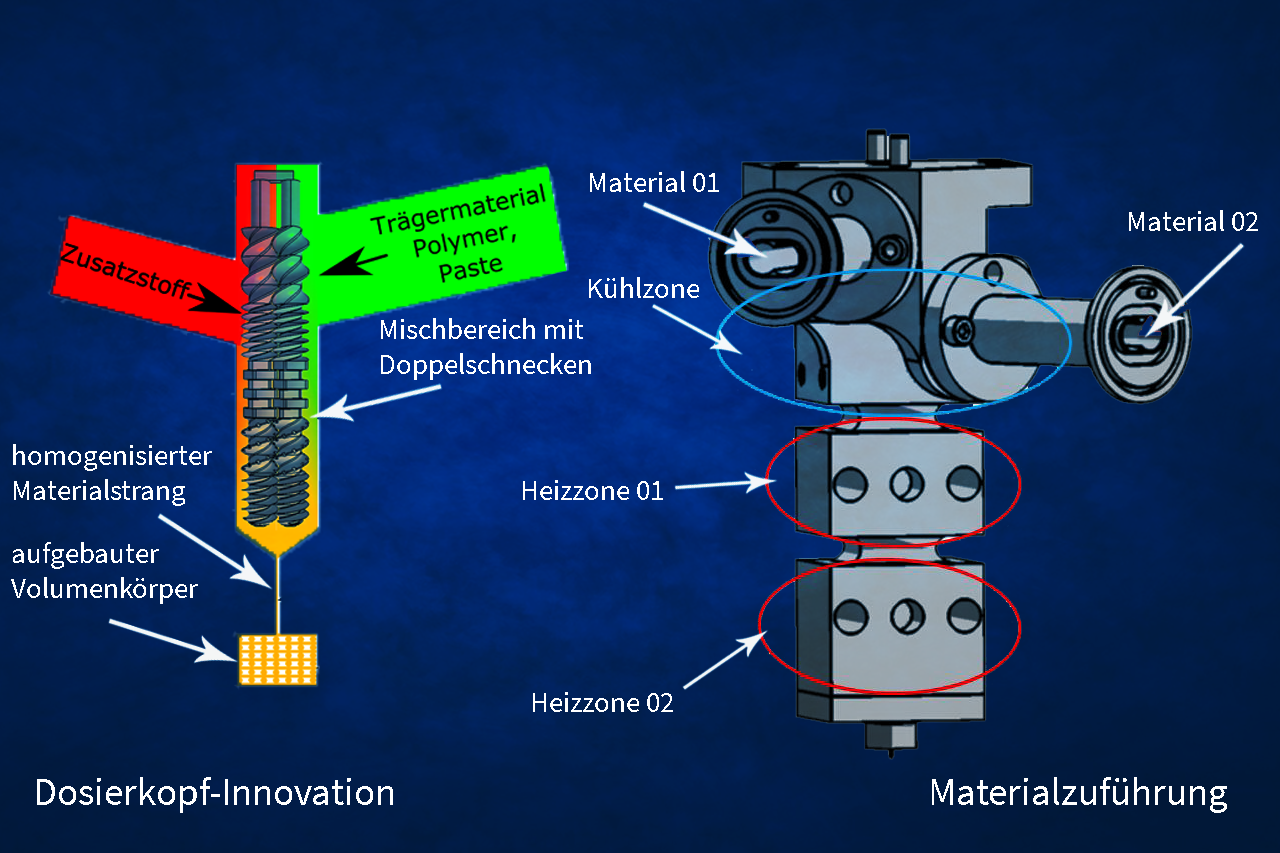

Development of a dosing head with twin-screw extruder

Development of a dosing head (FDM process) for additive manufacturing with integrated twin-screw extruder. This makes it possible to mix several materials during the 3D processing procedure. In addition, the processing temperature can be significantly reduced compared to conventional technologies and complex material mixtures can be processed. The aim is the three-dimensional construction of bone replacement materials.

Funding: SMWK

Project partners: Chair of Pharmaceutical Technology/Institute of Pharmacy/Faculty of Medicine/University of Leipzig, Clinical Pharmacology/Faculty of Medicine/University of Leipzig

Project duration: 05/2013 - 12/2014

Publication: A twin-screw extruder for material dosing in a rapid prototyping process

in: Stelzer, Ralph, ed., 2016. Entwerfen Entwickeln Erleben 2016 - Beiträge zur virtuellen Produktentwicklung und Konstruktionstechnik: Dresden, 30 June - 1 July 2016. Dresden: TUDpress - Verlag der Wissenschaften GmbH. PP. 419-428. ISBN 978-3-95908-062-0

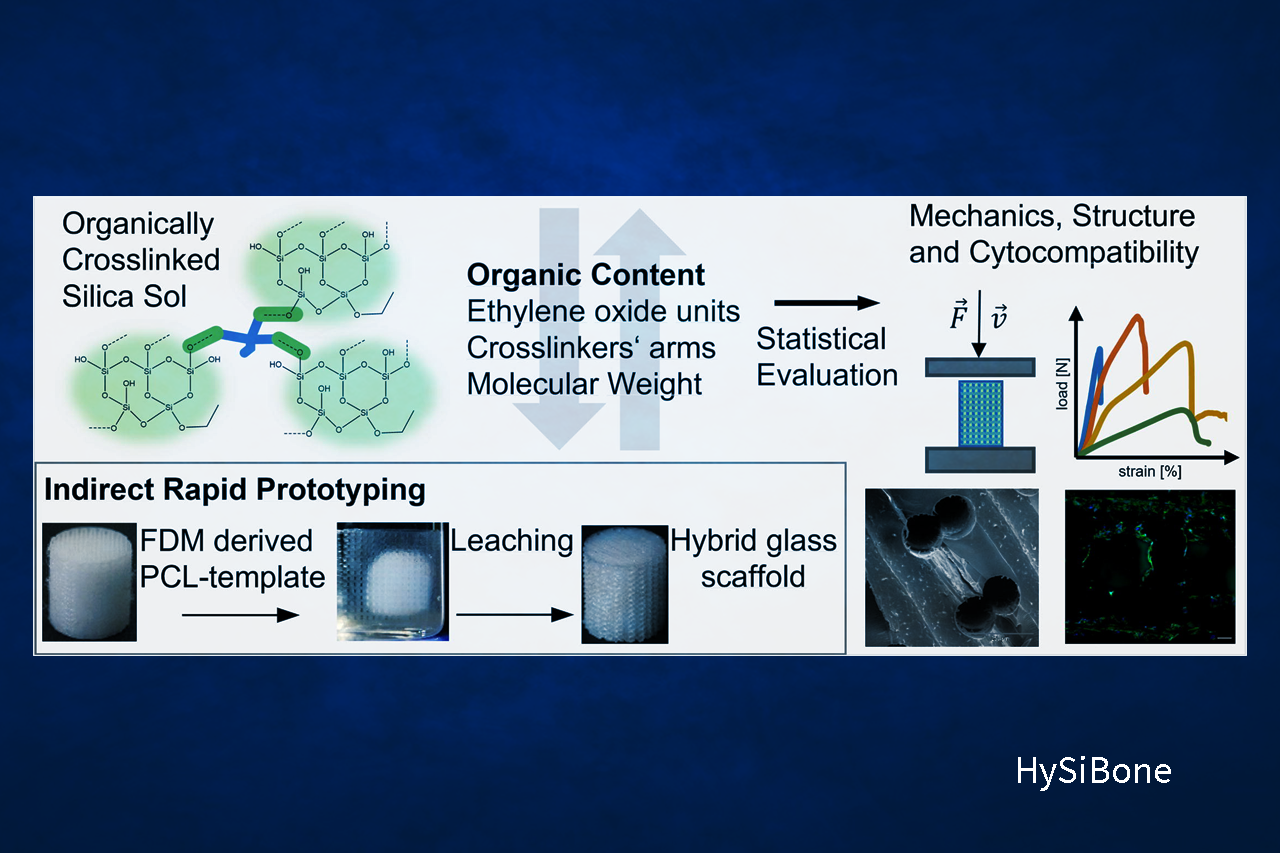

Development of a novel porous hybrid silicate bone substitute material

Use of the generative process Fused Deposition Modelling (FDM) for the production of moulded bodies. These serve as lost moulds for the indirect structuring of hybrid silicate materials as bone replacement materials.

Funding: ZIM of the BMWi (AiF)

Project partners: Chair of Pharmaceutical Technology/Institute of Pharmacy/Faculty of Medicine/University of Leipzig, Bubbles and beyond GmbH, DMG-Chemie GmbH

Project duration: 05/2011 - 07/2013

Patent: DE102014224654A1 | Macroporous, biodegradable organically cross-linked silicate hybrid materials for implantation

Publications:

- Indirect rapid prototyping of sol-gel hybrid glass scaffolds for bone regeneration - effects of organic crosslinker valence, content and molecular weight on mechanical properties

DOI: 10.1016/j.actbio.2016.02.038 - Effects of curing and organic content on bioactivity and mechanical properties of hybrid sol-gel glass scaffolds made by indirect rapid prototyping

DOI: 10.1007/s10971-017-4395-y - Biodegradable and adjustable sol-gel glass based hybrid scaffolds from multi-armed oligomeric building blocks

DOI: 10.1016/j.actbio.2017.09.024 - Sustained Calcium(II)-Release to Impart Bioactivity in Hybrid Glass Scaffolds for Bone Tissue Engineering

DOI: 10.3390/pharmaceutics12121192